Welcome back to phase 2 of our Paint issues article. This article will cover issues 21-30 in the list.

31 - Rust Rashing

32- Rust Spotting

33 - Rust Staining

34 - Paint Sags

35 - Paint Settlement

36 - Paint Skinning

37 - Solvent Lifting

38 - Solvent Popping

39 - Paint Staining

40 - Stress Cracking

41 - Undercutting

42 - Paint Wrinkling

For the previous article on Paint issues 1-10 covering ( Abrasion, Adhesion Failure, Alligatoring, Bleeding, Blistering, Bloom, Bridging, Bubbling,Cathodic Disbonding and Challking)

Paint issues 1-10 view it here.

Paint issues 11-20 view it here

Paint issues 21-32 view it here

Painting Issues Can Ruin A Good Project

A fantastic paint job can make any project come to life...however after application there can be any number of paint issues which can ruin the same project. In this article we're going to run through the main reasons for paint failures, why they happen, how to spot them and how to prevent them in the future.

The daunting element of painting is that there are so many potential pitfalls for painting failures the list is almost endless! However at Ultrimax we've collated the top 42 paint problems that can occur on a paint job and we'll discuss here the type of paint coating failures and defects – why they happen and possible causes for them.

View our Complete Video Guide to 42 Paint Problems Below:

Paint Problem 31 - Rust Rashing

Why It Happens

Rust Rashing brings us to defect 31 and is generally caused by low film thickness, often in combination with a high surface profile.

Example of Rust Rashing

How To Prevent It

A prevention of this is to ensure that an adequate thickness of a primer coat is applied to cover the surface profile, and check that the surface profile is not too large.

Paint Problem 32 - Rust Spotting

Failure 32 brings us to another rust related issue, rust spotting.

Why Does It Happen

You can identify rust spotting by dried iron salt deposits on a metal surface caused by corrosion. Probable causes of this can be low film thicknesses, voids and holidays.

Steel defects such as laminations and inclusions can also cause spotting as can a high surface profile with a number of peaks in the paint film. Another common cause is metallic contamination of a coated surface by grinding dust which then slowly corrodes.

Example of Rust Spotting

How To Prevent It

To prevent this, ensure that an adequate thickness of a primer coat is applied to cover the surface profile, use a thicker coating system or a lower blast profile and protect the coating from grinding dust contamination.

Paint Problem 33 - Rust Staining

At no 33 we are still with the rust family of issues.

Why It Happens

Rust Staining can be caused by water runoff from a rusty surface above a soundly coated surface. Rust staining contaminates water and discolours other items or locations. Usually more of an eyesore than a defect. The coating itself may not be defective, only stained but in the painting world that is still a problem to solve for the customer.

Example of Rust Staining

How To Prevent It

A prevention on this is to ensure adequate design to stop water run off and suitable maintenance of surrounding substrates.

Paint Problem 34 Paint Sags

At no 34 Sags is a very ugly defect for painters to deal with.

Why It Happens

When there is an over application of paint, excessive use of thinners, incorrect or lack of curing agent, or poor workmanship its likely you will cause a sagging or sliding of a coating. In extreme circumstances, it could also be a result of a formulation problem.

Example of Paint Sags

How To Prevent It

The only way to repair this kind of damage is to sand back and start from the beginning, so to ensure you prevent Sags, use the correct application techniques with suitably formulated products.

Paint Problem 35 - Paint Settlement

Defect 35 is Settlement.

Why It Happens

Settlement is when the paint colouration is not uniform across the whole coating and the inconsistent finish ruins the job. This is a very easily avoidable fault as the most likely cause is a lack of correct mixing at the formulation stage. Always ensure adequate mixing with a paint mixer to get best results. There are also other possible causes such as old stock or heavily pigmented paint as found with zinc-rich primers.

Example of Paint Settlement

How To Prevent It

To prevent this use products within shelf life, use adequate mixing procedures, and keep paint mixed or recirculated during spray application.

Paint Problem 36 - Paint Skinning

Problem 36 is Skinning.

Why It Happens

This can be caused by the absence of an anti-skinning agent in the paint, use of non-airtight containers or non original storage conditions and often occurs in partly used cans.

Example of Paint Skinning

How To Prevent It

To prevent this, use an airtight container and store according to the official data sheets.

Paint Problem 37 - Solvent Lifting

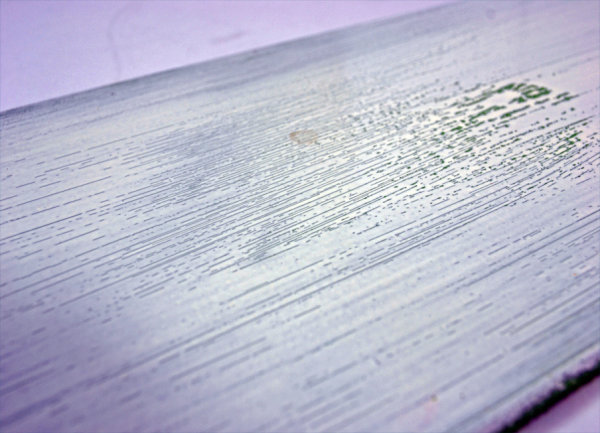

In example 37 Solvent lifting is yet another example of paint coating failures and defects. Solvent lifting looks like a cracked crater in a desert with ridges and flat areas throughout.

Why It Happens

It can be present when incompatible paint systems are being used together or a topcoat with a strong solvent blend reacts with a previous and weaker solvent-blended coating. Overcoating before the previous coat has adequately hardened is also a common cause of solvent lifting.

Example of Solvent Lifting

How To Prevent It

The best prevention of solvent lifting is to use the correct coating specification, overcoating times, and materials. Conduct compatibility trials with undercoats and topcoats.

Paint Problem 38 - Solvent Popping

At 38 we have Solvent Popping.

Why It Happens

An ugly defect like pimples on the skin, it’s caused by solvent evaporating so quickly from the wet film coat that the resulting void cannot be filled in time and a crater is left behind.

Example of Solvent Popping in Paint

How To Prevent It

Generally incorrect solvent blends, porous surfaces, incorrected environmental conditions, or high surface temperature are to blame for solvent popping showing up in a wet film. By using the correct coating specifications ,materials, application techniques and only painting in stable environmental conditions you can prevent Solvent Popping.

Paint Problem 39 - Staining

Staining is our defect no 39.

Why It Happens

When a solid or liquid imparts a discoloration to the coating you tend to be left with a stain.

Example of Staining When Using Paint

How To Prevent It

To prevent Staining avoid allowing the coating to come into contact with solids and liquids that are prone to cause staining or alternatively use dark-coloured coatings where any staining would not be so apparent.

Paint Problem 40 - Stress Cracking

Next up at no 40 is Stress Cracking.

Why It Happens

As the name suggests stress cracking can be attributed to surface movement, aging, absorption and desorption of moisture, thermal cycling, and general lack of flexibility of the coating. The thicker the paint film, the greater the possibility that cracking may occur. It often occurs around welds and changes in section that are difficult coat accurately.

Example of Stress Cracking

How To Prevent It

You can prevent Stress Cracking by using the correct coating systems and dry-film thicknesses, or use a more flexible coating system to compensate.

Paint Problem 41 - Undercutting

Defect 41 is Undercutting.

Why It Happens

It creates an effect that looks like one coating running into another with a thick edge. The most likely cause of this is application of paint to a corroded substrate. You may see rust creep from areas of mechanical damage which results in a missing primer coat. Undercutting often shows in areas of poor design and access, where inadequate preparation and coating thickness was applied. In these same areas maintenance may be difficult which can cause the undercutting to worsen.

How To Prevent It

To prevent this use adequate coating specifications and maintenance procedures and apply a suitably formulated primer.

Paint Problem 42 - Paint Wrinkling

We’re finally at the end of our mega list of paint failures and defects! Before we go though here’s one last defect – no 42 Wrinkling. As the name suggests this is when the coating surface contracts and forms a wrinkle.

Why It Happens

It can arise from overcoating before the previous coat has adequately hardened or cured and follow on effect of one coating layer drying while one is still wet - causes a reaction and wrinkle. Over application of a paint coating can be a cause, particularly with alkyd coatings as these types of material are naturally thicker making it easier to over apply.

Example of Paint Wrinkling

To Prevent It

To prevent wrinkles on your project use correct coating specifications from your technical datasheet, ensure you mix correctly and apply in thin layers to avoid overcoating. Forced curing with IR heaters will eliminate the risk of applying a layer to a wet coating.

So that’s it! If you need further help or information visit our website below.

Need More Help With Paint Issues?

If you can’t find a fix for the issue you’re experiencing or you need more advice Contact Us