Welcome back to phase 2 of our Paint issues article. This article will cover issues 11-20 in the list.

11 - Paint Checking

12- Paint Sissing

13 - Paint Cobwebbing

14 - Paint Cracking

15 - Paint Cratering

16 - Paint Crazing

17 - Paint Crows footing

18 - Paint Delamination

19 - Paint Fading

20 -Paint Flaking

For the previous article on Paint issues 1-10 covering ( Abrasion, Adhesion Failure, Alligatoring, Bleeding, Blistering, Bloom, Bridging, Bubbling, Cathodic Disbonding and Challking) view it here.

Painting Issues Can Ruin A Good Project

A fantastic paint job can make any project come to life...however after application there can be any number of paint issues which can ruin the same project. In this article we're going to run through the main reasons for paint failures, why they happen, how to spot them and how to prevent them in the future.

The daunting element of painting is that there are so many potential pitfalls for painting failures the list is almost endless! However at Ultrimax we've collated the top 42 paint problems that can occur on a paint job and we'll discuss here the type of paint coating failures and defects – why they happen and possible causes for them.

View our Complete Video Guide to 42 Paint Problems Below:

Paint Problem 11 - Paint Checking

Next we move onto Checking .

Why It Happens

This is typically caused by a formulation or specification problem. As with cracking, stresses are developed that cause the surface of the paint film to become brittle and crack. Another cause could be limited paint flexibility.

Example of Paint Checking

How To Prevent It

By using a correctly formulated coating system Checking can be prevented.

Paint Problem No 12 - Cissing

Cissing is next on our list of coating failures.

Why It Happens

This can be caused with surface contamination by moisture or a foreign material such as oil, grease, or silicone. Cissing is also common when incorrect solvent blends have been used in the original mix.

How To Prevent It

To prevent this ensure the surface is clean and free from grease, oil and other contaminants prior to application of a coating.

Paint Problem No 13 - Cobwebbing

At number 13 we have Cobwebbing.

Why It Happens

A probable cause could be too high a viscosity with some types of polymer. Cobwebbing will occur with chlorinated rubber paints at almost any viscosity.

Example of Cobwebbing Paint Issue

How To Prevent It

By reducing the spraying viscosity, selecting a more suitable solvent blend, and changing the spraying conditions you can prevent Cobwebbing from happening.

Paint Problem No 14 - Paint Cracking

Cracking is Number 14 on the list.

Why It Happens

Cracking is generally a stress-related failure and can be attributed to surface movement, aging, absorption and desorption of moisture, and general lack of flexibility of the coating. The thicker the paint film, the greater the possibility it will crack.

Example of Paint Cracking

How To Prevent It

To prevent this, use the correct coating systems, application techniques, and dry-film thickness levels. Alternatively, use a more flexible coating system to provide a buffer against cracking.

Paint Problem No 15 - Cratering

Cratering is our number 15.

Why it Happens

Cratering is trapped air or solvent bubbles that have burst on the coating surface, leaving small craters as the coating dries. The coating therefore has insufficient time to flow into a uniform film.

Example of Paint Cratering

How To Prevent It

To prevent Cratering, improve your spray technique, apply a mist coat, and avoid air entrapment during mixing. You can also add thinners as recommended by the paint supplier to reduce paint viscosity.

Paint Problem No 16 - Crazing

At 16 in our list of coating defects is Crazing.

Why It Happens

Another common paint problem crazing most often occurs when application temperature is too low or below 5 degrees. (check out our link above on temperature for a detailed guide) It can also be an issue if there is an incompatibility with previous coatings, aging, or if there is a high film thickness.

Example of Paint Crazing

How To Prevent It

To prevent Crazing apply a thinner coat of paint, add slower-drying solvent, check that application and drying conditions are correct for the paint system used, and check compatibility between previous coatings and the new coating.

Paint Problem No 17 - Crowfooting

Crowsfooting is example number 17

Why Does it Happen

Usually caused when the surface drys too quickly and forms a skin, which then wrinkles as solvent slowly evaporates from the soft underlying paint.

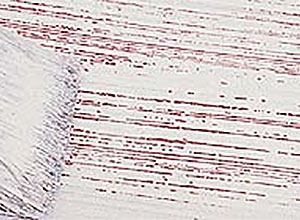

Example Of Crows footing In Paint

How To Prevent It

Very similar to Crazing in appearance, Crows footing can be prevented by applying a thinner coat of paint, adding slower-drying thinners and check that application and drying conditions are correct for the paint system used.

Paint Problem No 18 - Delamination

Number 18 failure is Delamination.

Why It Happens

Provided that compatible paint materials have been used, delamination defects are generally related to poor surface preparation and application. Contamination between coats, exceeding overcoat times, or application to a glossy surface are the most frequent culprits causing delamination.

Example of Delamination

How To Prevent It

To prevent this, ensure that no contamination occurs between paint coats. Follow the recommended overcoating ‘flash’ intervals. Lightly abrade and clean glossy surfaces between coats.

Paint Problem 19 - Paint Fading

At 19 Fading is another routine paint problem facing regular sprayers.

Why This Happens

This can be caused by incorrect pigmentation, use of non-light-stable organic pigments, atmospheric contamination or a porous substrate that leaches away the original colour.

An Example of Paint Fading

How To Prevent It

To prevent fading, use correct coating systems that resist ultraviolet light and fading. Use a coating with light-stable pigments to retain bright colours.

Paint Problem 20 - Paint Flaking

No 20 is Flaking an issue most industrial painters will have faced at some point.

Why It Happens

Flaking is most often caused by using an incorrect paint system, for example using interior paint on an exterior object will most likely see flaking soon after drying.

Example of Paint Flaking

How To Prevent It

Either no or an incorrect pre-treatment used for certain substrates can cause flaking, for example on nonferrous or galvanized metals. Poor application techniques may also be attributed to differential expansion and contraction of paint and substrate.

Natural products such as wood are good examples of surfaces which expand and contract and can cause flaking. It can also be caused as a result of normal aging over time …for which there is no cure!

To prevent Flaking, use the correct coating system and pre-treatment.

Get The Next Instalment Of Paint Issues - Explained

For our next section of Paint Problems numbers 21-30 Check out the link here.

Need More Help With Paint Issues On Your Project?

If you can’t find a fix for the issue you’re experiencing or you need more advice Contact Us