Painting Issues Can Ruin A Good Project

A fantastic paint job can make any project come to life...however after application there can be any number of paint issues which can ruin the same project. In this article we're going to run through the main reasons for paint failures, why they happen, how to spot them and how to prevent them in the future.

The daunting element of painting is that there are so many potential pitfalls for painting failures the list is almost endless! However at Ultrimax we've collated the top 42 paint problems that can occur on a paint job and we'll discuss here the type of paint coating failures and defects – why they happen and possible causes for them.

View our Complete Video Guide to 42 Paint Problems Below:

Applying Paint and Paint Problems

Paint will be applied in diverse environmental conditions and is then expected to protect the substrate from the damaging effects of rain, sunlight, wind, heat, cold, humidity and oxygen to name a few!

As well as repel atmospheric conditions the coating must maintain its structural integrity and of course lets not forget we need it to look good too!

Paint Problem 1 - Abrasions

So lets look at our first paint defect type Abrasions.

Why it Happens

Abrasion defects happen when a portion of the surface coating is damaged or, in severe cases completely removed exposing the original substrate.

This often occurs through contact with another object, such as the use of metal chains for lifting, cargo scrapes, fenders, or even the grounding of a ship.

Paint Abrasion Example

Paint Abrasion Prevention -

You can prevent Abrasion with the use of abrasion-resistant coatings formulated with resins and extender pigments included which resist abrasion effects. In severe cases of abrasion, the effects may be limited by an abrasion-resistant coating, however impact damage is very difficult to prevent with a coating alone.

Paint Problem 2 - Adhesion Failure

Our second example of failures and defects in paint coatings is Adhesion Failure.

Why It Happens

This could be because the surface suffers from contamination or condensation, an incompatibility between coating systems or exceeding the overcoating time.

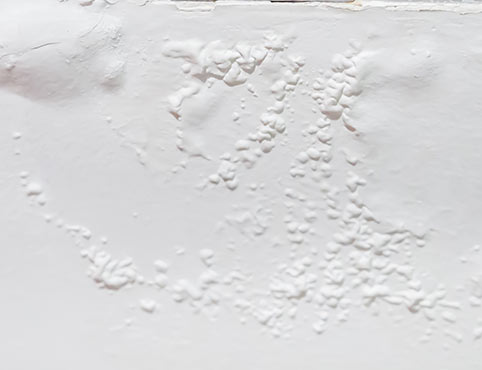

Paint Adhesion Failure Example

How To Prevent It

By ensuring that the surface is suitably prepared, clean, dry and free from contamination and by using the correct coating specification with recommended overcoating times followed, you can prevent Adhesion Failure.

Paint Problem 3 - Alligatoring

Example 3 is Alligatoring or (Crocodiling).

No wildlife here! This failure is caused by internal stresses in the coating where the surface shrinks faster than the body of the paint film causing an effect that looks like crocodile skin.

Why It Happens

It’s often caused by excessive film thickness and limited paint flexibility. For example if a hard top paint is coated over a more flexible softer undercoat or the application of a topcoat before the undercoat has dried.

How To Prevent It

Alligatoring can be prevented by using the correct coating specification shown in the technical datasheets. It can also be prevented by avoiding excessive film thickness and avoiding application at high ambient temperatures.

Paint Problem 4 - Paint Bleeding

Failure 4 is Bleeding.

Why It Happens

Bleed through is generally a full or partial redissolving of the previous coat or an ingredient of a previous coat and can occur when strong solvents are used in the topcoats.

Paint Bleed through Example

How To Prevent It

Bleeding can be prevented by using the correct coating specification and materials. By using compatible materials from the same paint system and using appropriate sealer coat if possible.

Paint Problem 5 - Paint Blistering

Next up we have Blistering.

Why Does It Happen

There can be many reasons for blistering and it’s a common coating fault. Many factors can be involved here including osmotic gradients associated with soluble salts, soluble pigments, corrosion products, retained solvents and solvents from cargoes to name a few.

An example of Paint Blistering

Non-osmotic blistering is associated with cathodic Dis-bonding, thermal gradients related to cold-wall effects, and compressive stress.

How To Prevent It

To prevent blistering, ensure that you have the correct surface preparation and application. Apply a suitable coating system after testing for soluble salts with a Positester by DeFelsko.

Consider which of the mentioned blister mechanisms may appear in the environment you are painting in and try to rectify it before painting.

Paint Problem 6 - Paint Blooming

Failure number 6 is Blooming or (Blush).

Why Does It Happen?

This could be because the paint film was exposed to condensation or moisture during curing, especially at low temperature, which is a common phenomenon with amine-cured epoxies. Incorrect solvent blend can also contribute to blooming.

An Example of Paint Blush or Blooming

How To Prevent It

To prevent blooming apply and cure coating systems under correct environmental conditions (ideally not in heavy moisture) and follow the manufacturer’s recommendations.

Paint Problems 7 - Paint Bridging

Lets move on to Bridging which is another common example of coating failures.

Why It Happens?

Bridging is mainly a human error coating failure. Caused by poor application to the surface, a high-viscosity paint system and failure to brush paint into corners and over welds.

An example of Paint Bridging

How To Prevent It

Bridging can be prevented by brush-applying a stripe coat into corners and welds and fill all cracks or weld them prior to application of the full coating system. It is extra work but may prevent costly paint repairs in the future.

Paint Problem 8 - Paint Bubbling

Failure no 8 is Bubbles or Bubbling.

A probable cause of this is trapped air or solvent within the coating that is not released before the surface dries. Air could have become entrapped during the mixing phase or a high ambient temperature during application can also cause significant bubbling.

An example of Paint Bubbling

A special note when painting in marine situations and applying antifoul layers. If you overcoat the antifoul layer without first removing the leached layer and zinc silicates, you may find your entire paint finish will bubble and need re-pairing and re-finishing. This can also be found with factory-applied coatings where application is by dipping, electrodeposition, or roller coating.

How To Prevent

In spray application, bubbling can be prevented by adjusting the viscosity with thinners and following data sheet requirements for maximum application temperature. Use correct mixing equipment (such as a paint shaker)to ensure air is not stirred in during mixing. Apply a mist coat and add de-foaming agent to emulsion paints.

Paint Problem 9 - Cathodic Disbonding

At number 9 we have Cathodic Disbonding.

Why It Happens?

A probable cause is high overvoltage principally from impressed current systems, but also to a lesser extent with sacrificial anodes when the number of anodes is excessive. Factors are incorrect installation, poor monitoring, and incompatible coating systems.

An Example of Cathodic Disbonding

How To Prevent It

To prevent this issue, use a well-designed cathodic protection system, regularly monitored with well-placed reference electrodes, and application of an alkali-resistant coating system will solve any future occurrence.

So this brings us to our final paint problem of this section of the article ...but wait didn't we promise you 42 paint problems?

Not to fear we've created some further articles explaining the next 30+ paint issues you may face on your project. See the bottom of this article for access to those articles.

Paint Problem 10 - Paint Chalking

At number 10 we have chalking which is another common failure occurrence.

Why it Happens?

A probable cause of this is disintegration of the paint binder on exposure to weathering and or ultraviolet light which causes a powdery chalk like substance to appear on the surface.

An example of Paint Chalking

How To Prevent It

To prevent Chalking apply a suitable topcoat with high resistance to chalking and with ultraviolet resistance.

Need More Help With Paint Issues on Your Project?

If you can’t find a fix for the issue you’re experiencing or you need more advice contact us